Americas

Europe, Middle East, Africa

Asia Pacific

.jpeg?sfvrsn=0&MaxWidth=1200&MaxHeight=800&ScaleUp=false&Quality=High&Method=ResizeFitToAreaArguments&Signature=82D0DBF4B5916A89AF73818B40C7B990A06C4815)

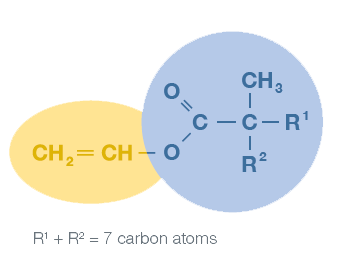

VeoVa™ 10 monomer is the vinyl ester of Versatic™ acid 10. The homopolymer of VeoVa 10 monomer has a relatively low Tg of -3 °C. VeoVa 10 monomer can be used as a modifying comonomer in the preparation of vinyl acetate based polymer latices, which are used for the manufacture of high-quality emulsion paints. VeoVa 10 vinyl ester is also used as a comonomer with acrylates for the production of emulsion and solution polymers.