Americas

Europe, Middle East, Africa

Asia Pacific

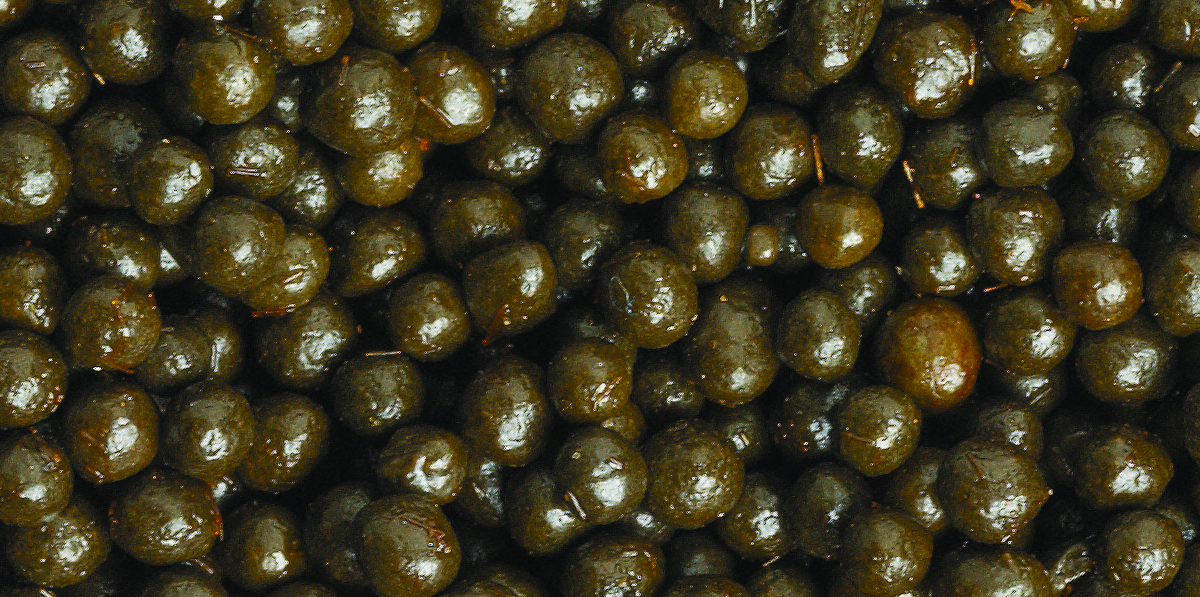

XRT™ Ceramax™ P proppants are designed to be the highest strength proppants available. Use of the eXtreme Resin Technology (XRT) system to encase a high density bauxite has yielded a proppant with high conductivity and resistance to cyclic stress.

Fracture treatments:

| Property | Standard | Value | Unit | Test Method |

|---|---|---|---|---|

| API Mesh Size | 20/40 | |||

| Bulk Density | 1.92 [16.0] | g/cm³ [lb/gal] | ||

| Color | brownish-black | |||

| Compatibility | Fully compatible with most commonly used fracturing fluids, both water and oil-based systems. Testing with fluids prior to pumping is advised. | |||

| Composition | resin coated bauxite | |||

| Particle Size Distribution | meets or exceeds API RP 19C | |||

| Physical State | solid granule | |||

| Pipe Fill Factor | 0.521 [0.0625] | cm³/g [gal/lb] | ||

| Resin Type | thermosetting, curable | |||

| Solubility in Water, Brine & HCl | nil | weight % | ||

| Solubility in HCl/HF acid, API RP 19C | ≤ 3 | weight % | ||

| Solubility In Oil | nil | weight % | ||

| Specific Gravity | 3.43 | |||

| Specific Volume | 0.292 [0.0350] | cm³/g [gal/lb] | ||

| Turbidity | < 500 | NTU (FTU) |

1 XRT Ceramax P uses bauxite, which is the highest strength ceramic. Conductivity testing conducted up to 14,000 psi.