Hexion’s Sentinel dust suppressant mitigates the respirable silica dust generated by uncoated sand. This economical solution is designed to reduce the amount of respirable silica to levels below the new OSHA action level of 25 µg/m3. The unique chemical system traps fine dust particles and remains on the proppant during transportation and transfer. The versatile application method allows users to apply the product at the sand mine, transload or at the location. Our Sentinel dust suppressant helps provide safety and compliance from the sand mine to the wellhead.

For More Information: oilfield@hexion.com.

Both the Sentinel dust suppressant treated 100 mesh sand and uncoated 100 mesh sand were transferred to an open bin by a mobile conveyor. A vertical fall of approximately 25 feet generated respirable dust levels above the new OSHA PEL for the uncoated 100 mesh sand. The 100 mesh sand treated by the Sentinel dust suppressant had all respirable dust measurements below the new OSHA PEL. Analyzed in accordance with OSHA 1910.1053 appendix A.

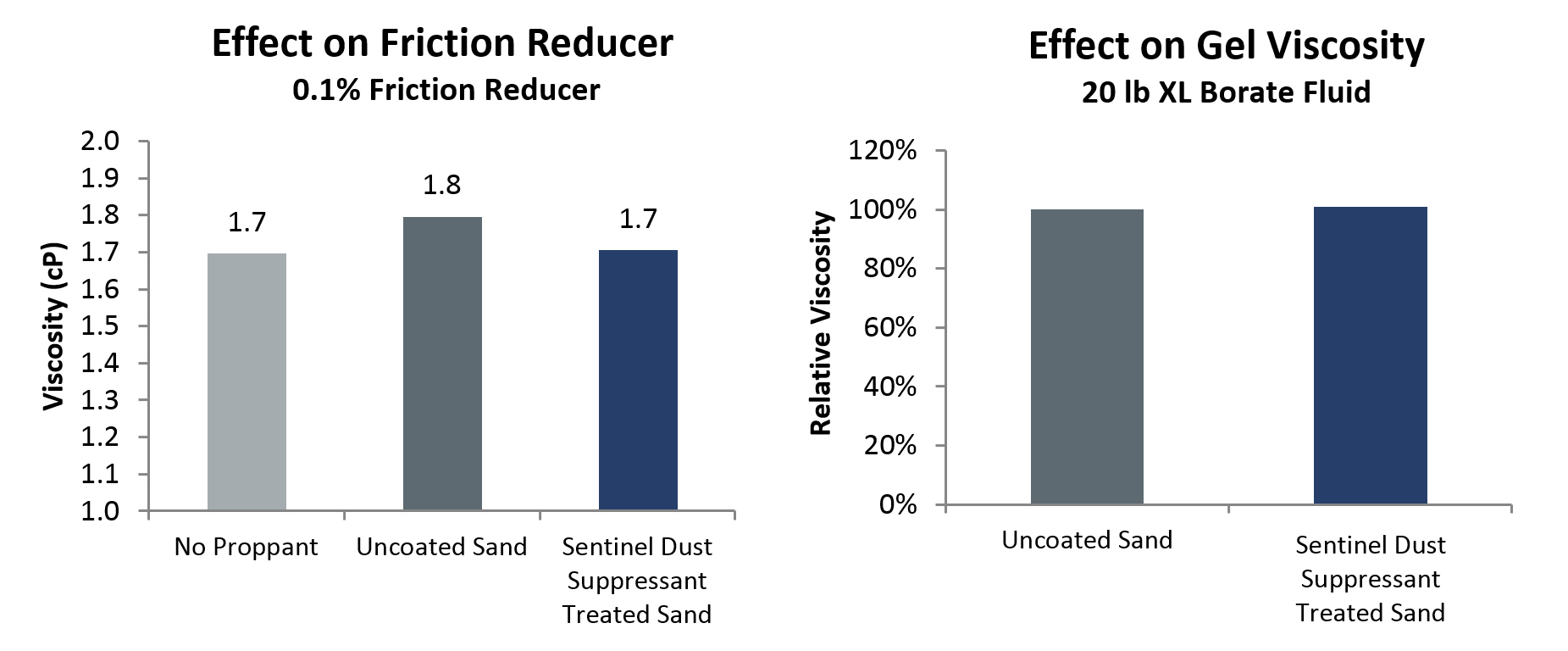

Sentinel dust suppressant shows negligible effects on commonly used frac fluid components when compared to uncoated sand.

There is virtually no impact on friction reducers or gelling agents when compared to uncoated sand. Hexion’s Sentinel dust suppressant is compatible with most commonly used fracturing fluids, both water and oil-based systems. Testing with fluids prior to pumping is advised.

The application mechanism only requires compressed air and can be configured to fit virtually any vertical fall. Hexion’s Sentinel dust suppressant is composed of a single chemical that does not require any mixing systems or dilution.

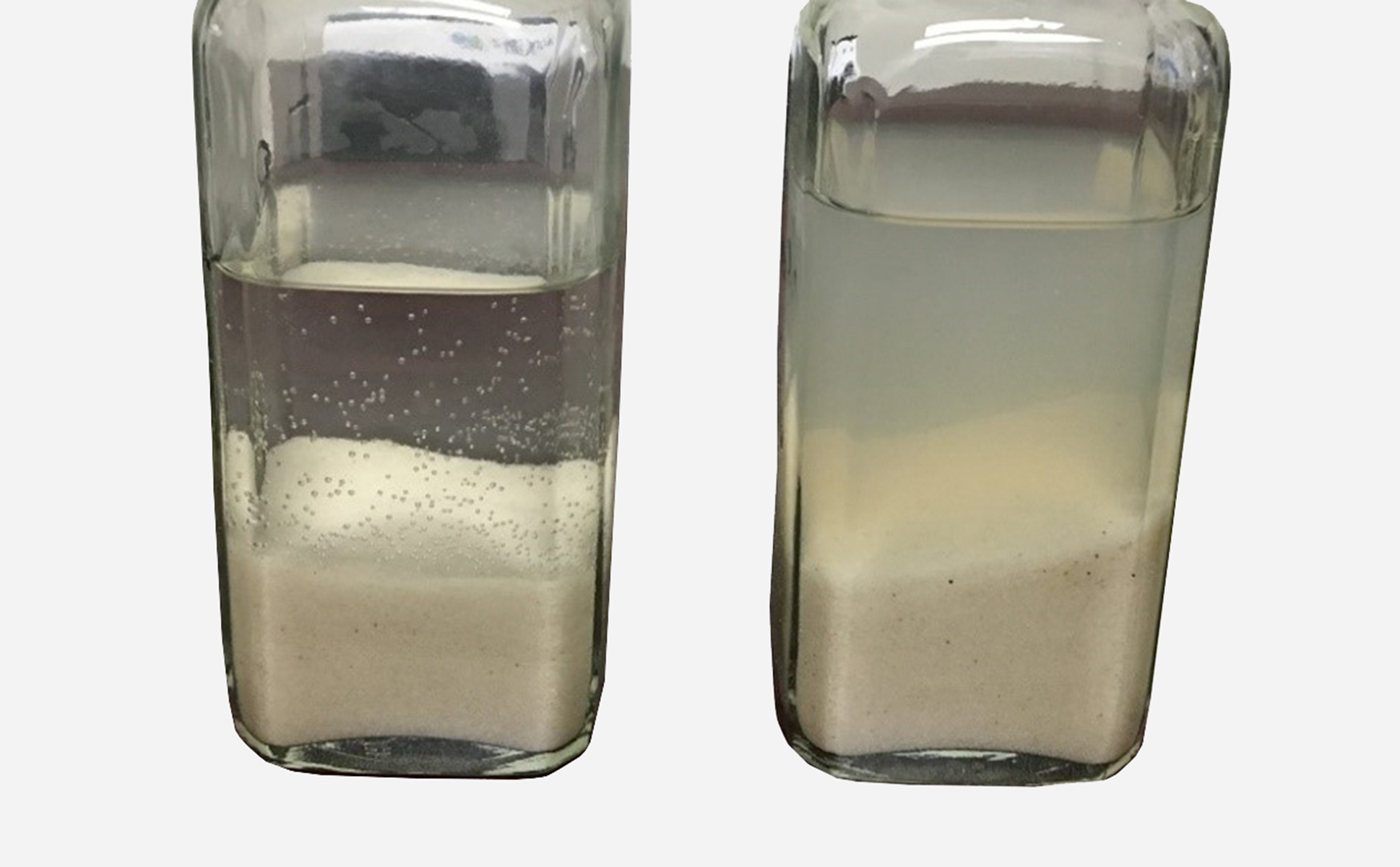

An independent third party laboratory tested conductivity on low turbidity sand and high turbidity sand. The conductivity of the high turbidity sand was up to 38% lower compared to the conductivity of the low turbidity sand. The dust particles that cause high turbidity are also contributing to the reduction of the proppant pack conductivity. The photo below compares the turbidity of frac sand treated with Hexion’s Sentinel dust suppressant to the turbidity of untreated frac sand.